Carbon capture optimisation: add heat, reduce risk

While a range of carbon capture (CC) technologies are available to the cement industry, not all are a suitable option in terms of cost and risk. Ramboll looks at the benefits of an integrated amine-based solution. By Thomas Paarup Pedersen, Andrea Meroni, Christian Riber and Burcin Temel Mckenna, Ramboll, Denmark.

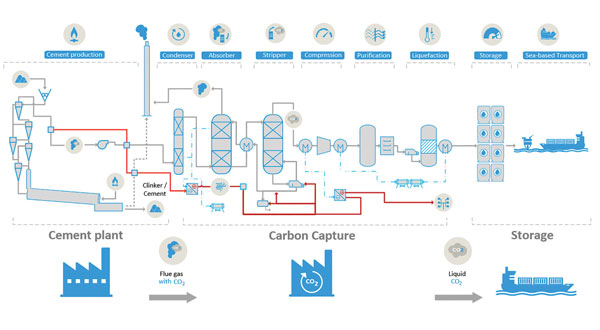

Figure 1: simple process flow diagram of a cement plant with carbon capture, CO2 purification and liquefaction,

and export. Red lines indicate heat recovery and integration in the carbon capture plant (Source: Ramboll)

The challenge for cement production is that the most mature carbon capture (CC) technology developed for large combustion plants – amine-based absorption – relies on extensive amounts of medium-high temperature heat, which is not available in sufficient quantities at a typical cement plant. In this case, alternative ways of sourcing the heat, or alternative processes, such as chilled ammonia, hot potassium carbonate (HPC), cold potassium carbonate (CPC), oxyfuel (combustion with pure oxygen instead of air) or cryogenic capture are considered.