SNCR: when the equation no longer holds

There are plants where selective non-catalytic reduction (SNCR) does not achieve the expected DeNOX results for no apparent reason. Often a look at the chemical processes in the background provides a clue as to why successful denitrification is failing. By Karin Koglbauer, DyCarnica, Austria.

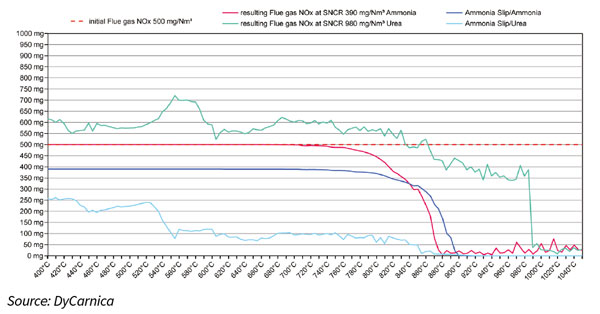

Figure 1: chemical DeNOx behaviour-ammonia vs urea (© DyCarnica)

Selective non-catalytic reduction (SNCR) refers to selective flue gas denitrification without a catalyst at 800-1100˚C. Growing experience and the introduction of fluid-mechanic knowledge has led to flow optimisation, optimisation of droplet distribution and the determination of optimum injection positions. In many cases, this has seen increasingly better denitrification results. Nevertheless, there are cases in which these measures do not have the desired effect. At present, the only way out is to look in the direction of selective catalytic reduction (SCR). Here, a closer look at reaction chemistry can certainly be beneficial.

SNCR involves either using ammonia or urea as reactants. However, despite their apparent similarity, ammonia and urea display distinct chemical behaviours that impact the design and efficacy of denitrification systems (see Figure 1). Denitrification always occurs with ammonia, even when urea is injected and decomposes into ammonia as part of the process.

The simple reaction equation on which SNCR is said to operate seems widely known:

NH3 + NOx => N2 + H2O

However, there is much more behind it than first appears. This reaction is a synproportionation of the nitrogen atoms in the molecules involved in the reaction. The NOx molecule is a very reactive (oxidising) one, while the NH3 molecule is quite stable. Therefore, the NH3 must be cracked to NH2, which is normally achieved by the application temperature. The real reaction equation is in fact:

NH2 + NOx => N2 + H2O

And this cracking reaction of NH3 starts at 800˚C – hence the application temperature mentioned.

With urea, the situation is even more complicated. The large urea molecule decomposes very easily, starting at temperatures of around 400˚C. However, since undesirable reactions of the fragments dominate here, effective denitrification does not start until around 1000˚C. These unwanted reactions show their effects in the form of a urea-induced NOx increase below 850˚C. In the process, urea breaks down into the valuable NH2 but also into isocyanic acid (NHCO). The latter is a very reactive molecule that decomposes via intermediates to NOx, CO2 and H2O. In this process, the N2 formed earlier is mostly consumed again.

This can be seen from the fact that, despite decomposition of the urea below 800˚C, practically no ammonia slip can be detected. Not until about 1000˚C are the synproportionation reactions sufficiently faster than the secondary decomposition reactions and then the denitrification proceeds as expected.

The key to SNCR chemistry knowledge

But how do you obtain this knowledge, and how can you beneficially use it? Austria-based DyCarnica has spent several years designing what may be the most accurate computational model for gas reactions in SNCR. All relevant reactions of gas-phase nitrogen chemistry and, especially for urea, also gas-phase carbon chemistry are considered. This enables the company to uncover and counteract the reaction chemistry weaknesses of SNCR installations.

DyCarnica’s Cleanbustion database enables companies to assess their SNCR process and

determine if performance limits are reached (© DyCarnica)

One result of this development is the now freely accessible Cleanbustion SNCR database. Here 1,900,000 calculated SNCR states for ammonia and urea are available. This way, anyone interested can quickly and easily access the company’s computation results and get a picture of their SNCR process. The database enables the ability to determine if a plant has reached its performance limits. In addition to the open data, there is always the possibility of an individual SNCR audit.

Re-establishing the equation

However, how should we proceed if the equation no longer holds, or in other words, the efficiency of denitrification falls short of expectations?

Here, a step-by-step approach has emerged as useful. It is often helpful to carry out a chemical evaluation of the reaction conditions before carrying out computational fluid dynamics (CFD). In this way, it can be determined with little effort if all chemical preconditions for efficient denitrification are basically fulfilled at the plant.

If essential chemical requirements are missing, even excellent flow control cannot compensate for this. The results of the evaluation provide the first important indications of potential risks and performance losses. This also allows recommendations to be derived for improvements in the reaction process, on which the downstream engineering is based. A typical utilisation of the results takes place in the selection of the injection location for the reagent. This provides essential information for the CFD.

Another use case of the reaction-chemical calculation is the determination and verification of performance guarantees issued by SNCR suppliers. In many cases, SNCR suppliers are faced with the challenge of determining valid performance guarantees. This process is already demanding for a constant plant condition. If changing operating conditions prevail, eg, due to variation of the exhaust gas quantity and/or composition, the manufacturer risk increases immeasurably. A computational model like that of DyCarnica can be usefully applied here to assist. All probable operating conditions can be simulated and performance curves constructed on the basis of these results. Those, in turn, then serve as the basis for granted performance guarantees from SNCR suppliers.

Enabling a complete SNCR assessment

It is always the combination of fluid mechanical and reaction chemical approaches that allow a complete statement about the condition of a SNCR denitrification plant. The results of both aspects support and complement each other to form a valid overall picture.

This article was first published in International Cement Review in November 2023.