Grinding for green goals

As a key decarbonisation path, the research and application of low-carbon cement grinding technology and equipment can help reduce power consumption and improve clinker quality. Research by Sinoma International Engineering Co (China) reveals how to improve the grinding efficiency of bed comminution and separator efficiency while achieving low system resistance and optimal particle classification. By Chuanjie Song, Hefei Cement Research & Design Institute Co Ltd and Anhui Key Laboratory of Green and Low-Carbon Technology in Cement Manufacturing), China, and Lin Gao, CNBM (Hefei) Powder Technology Equipment Co Ltd and Anhui Key Laboratory of Green and Low-Carbon Technology in Cement Manufacturing, China

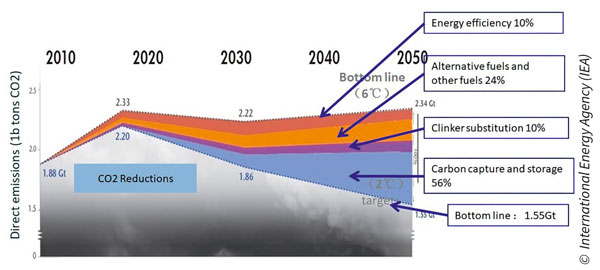

Figure 1: carbon emissions reduction roadmap for the cement industry by the International Energy Agency (IEA)

Decarbonation technology paths include optimising energy efficiency, the use of alternative fuels, clinker substitution and carbon capture and storage (see Figure 1). Sinoma International Engineering Co focusses on two research areas in the field of low-carbon cement grinding technology:

1. reducing power consumption

2. optimising particle size to improve clinker quality.

This article covers the first of these areas, including improving grinding efficiency of bed comminution, separator (classifier) system efficiency, low system resistance and optimal particle classification.