In the first of a series of articles for ICR, Kline Consulting explores the impact that reducing carbon emissions could have on the design of cement plants of the future. The three traditional CO2 reduction levers – namely energy efficiency (fuel and power), fuel CO2 reduction and clinker substitution – will all be considered in detail, as will the role of carbon capture technologies. In this first article, the author focusses on clinker substitution and the changes that may be required to enable the high-level utilisation of supplementary cementitious materials (SCMs). By John Kline & Charles Kline, Kline Consulting, USA.

CO2 emission reductions will have a profound impact on the way we conduct our lives in the future. Cutting CO2 emissions from cement manufacture will drive the evolution of the production process for the coming decades, while combining the optimisation of the three traditional CO2 reduction levers with carbon capture technologies could drastically change the processes used in traditional cement manufacture.

CSI road map

The International Energy Agency (IEA) has been developing “Blue Map” scenarios for CO2 emissions that would limit the increase in CO2 concentration in the atmosphere to 450ppm by 2050. The basis for the IEA target is an estimated average increase in global temperatures of 2°C. This goal requires a 50 per cent decrease in CO2 emissions from the 2007 baseline and limits global emissions to 14Gt of CO2.

The IEA has developed industry-specific targets required to meet the Blue Map goals which take into account the overall ease and cost of achievement within each industry sector. The cement industry is estimated to emit approximately five per cent of the global anthropogenic CO2 emissions. Concrete, the ultimate end product of cement, has a relatively small carbon footprint when compared to other construction materials. However, the extensive use of concrete leads to large global emissions. Therefore, the cement industry is expected to contribute CO2 emissions reductions accordingly.

Through the World Business Council for Sustainable Development (WBCSD) and the Cement Sustainability Initiative (CSI), the cement industry and the IEA have worked together to develop an industry-specific roadmap. This roadmap outlines the strategy to achieve the CO2 reduction targets set and establishes a corresponding action plan and timeline. The main levers identified and resulting emission reductions are shown in Figure 2.

Clinker substitution

Pure cements are made with approximately 95 per cent of clinker and five per cent gypsum. Over the years other ingredients, some inert and some with cementitious properties, have been added. Increasing the use of Supplementary Cementitious Materials (SCMs) reduces the amount of clinker in the cement binder, thus lowering the amount of CO2 released in cement manufacture. As ‘cement’ is often used to describe a pure cement (>90 per cent) the term ‘binder’ will be used here to describe cements that have a high level of SCMs (clinker <90 per cent). Clinker substitution is expected to deliver 10 per cent of the required emissions reduction.

SCMs

There are a number of natural and artificially-produced materials that have cement-like or cementitious properties. Three basic groups of cementitious materials exist:

1. Hydraulic binders react with water in forming the calcium silicate hydrate (C-S-H), which is responsible for the setting and strength of concrete. Hydraulic binders contain a significant amount of CaO, such as lime, steel slag, and class C flyash. Materials that ‘set’ or react with water addition are broadly classified as hydraulic.

2. Pozzolanic binders do not react with water and primarily contribute silica to the C-S-H reactions. The cementitious contributions from pozzolanic materials depend greatly on the form of the silica in the material. The pozzolanic reactions are slower than hydraulic reactions and increase later strength (>28 days) potentially at the expense of early strength. Some common pozzolanic materials include class F flyash, silica fume, volcanic ashes and calcined clays. In this article pozzolans will refer to naturally occurring pozzolans. Manufactured and waste pozzolans will be referred to as ‘artificial’ pozzolans.

3. Inerts are essentially fillers in the cement. The most common inert material used today is limestone. Finely-ground limestone is added to cement in many countries around the world. Inert materials do not react with the binder in concrete, nor do they have any deleterious effects, but they fill voids in the concrete and can add nucleation sites for the hydraulic reactions. Figure 3 compares the chemical compositions of some of the more common SCMs.

Today SCMs are combined with OPC at the cement manufacturing facility (European model) or at the concrete batching plant (North American model). Inside the cement plant, the SCMs can either be interground in the same process, or ground separately and blended. In the case of separate grinding, one or more of the ingredients can be ground off site.

Flyash

Flyash is the residual ash from the combustion of solid fuels that is captured in the dust collection equipment. Fineness is typically impacted by fuel grinding, but agglomeration can occur as well. The most common contaminant of interest is the amount of unburnt carbon in the flyash and quality can be enhanced through a number of ‘beneficiation’ processes. The most common beneficiation processes are geared towards removing or reducing the impact of unburnt carbon. Size classification is also used to improve reactivity. Figure 4 identifies global coal consumption by country.

Slag

Ground granulated blast furnace slag (GGBS) is widely used as a cement substitute. Blast furnace slag is a byproduct of iron production, where limestone or dolomite is added to the molten metal to extract the silica and alumina impurities. When rapidly quenched by air or water, the slag hardens into an amorphous, glassy structure rich in calcium silicates. Granulated slag can perform similarly to Portland cement when finely ground. Pure ground slag usually has slower set times and lower early strengths, but higher later strengths (>56 days) than OPC. Slag availability will be concentrated in countries with significant iron production as indicated in Figure 5.

Pozzolans

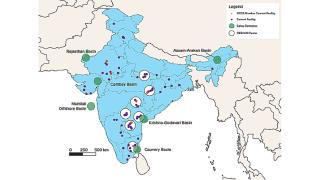

Natural pozzolans are materials rich in silica that result primarily from volcanic activity. The reactivity of the pozzolan depends on the specific chemistry of the pozzolan and often its age. More recent volcanic activity typically gives a more reactive pozzolan, which can be added at a higher substitution rate. Figure 6 indicates areas with recent volcanic activity, where reactive pozzolans should be available. The CSI estimates that 300Mta of pozzolans are available, but that only half that amount is being used.

Artificial pozzolans can be created with calcined clays and sometimes shales. In this process the material is heated to the point (700-900°C) where the internal crystalline structure is broken, resulting in amorphous silicates. The processes can approach the cost of producing clinker, therefore strong financial incentives will be needed to advance this option.

Table 1 indicates a rough estimate of SCM usage today and the substitution potential if all currently-available SCMs are used.

|

Table 1: present SCM substitution and potential maximum substitution |

||||

|

|

Present substitution estimate (Mta) |

Share in binder (%) |

Volume available (Mta) |

Maximum share of binder (%) |

|

Clinker |

2780 |

77 |

2780 |

69 |

|

Gypsum |

120 |

3 |

120 |

3 |

|

Flyash |

250 |

7 |

500 |

12 |

|

Slag |

150 |

4 |

200 |

5 |

|

Natural pozzolans |

150 |

4 |

300 |

7 |

|

Artificial pozzolans |

0 |

0 |

0 |

0 |

|

Limestone |

150 |

4 |

150 |

4 |

|

Total binder |

3600 |

100 |

4050 |

100 |

Maximising SCM content

To maximise the amount of clinker substitution, the maximum potential needs to be obtained from each of the binder ingredients. The natural starting place is to ensure that the binder components are the best possible. In addition, improving the base reactivity and performance of the clinker and substitute materials also contribute significantly to building a solid foundation for raising substition quantities. SCM performance can often be enhanced through further processing and the addition of chemical additives.

One important way to enhance performance is to increase the surface area for reaction which leads to an improvement in all reaction rates. In concrete production this results in a quicker and more complete reaction of the binder providing higher strength.

Increasing the surface area of the material requires additional grinding which requires extra power so there will always be a trade-off between the energy requirement for grinding and the increase in reactivity (substitution) of the materials. In the future, this compromise will also be driven by the cost of CO2 avoidance. Each binder component will have its own, unique fineness/reactivity optimum in relation to power consumption (see Figure 7). The increasing cost of CO2 will drive the optimum points to even higher finenesses and increase the value of the clinker substitutes.

Each clinker substitute material will have its own specific material characteristics that will define the fineness-versus-power relationship. Harder materials will have a steeper power curve than softer materials. It may be difficult to achieve the optimum fineness for individual components when they are ground together. Therefore, optimising the binder of the future may require that different binder components are ground independently. Separate grinding allows the individual clinker substitutes to achieve their own specific optimum fineness and maximum substitution rates.

One rule will always exist, regardless of whether SCMs are ground separately or interground: if the rate of clinker substitution increases then the fineness of the binder components will have to increase to maintain similar concrete properties. Therefore, future plants should expect to grind all binder components to a higher fineness than today.

Impacts on future cement plants

Achieving higher levels of clinker substitution will call for more sophisticated binders, requiring a higher level of quality control and precision performance. This is best achieved if all components are independently controlled and accurately blended.

Binders sold according to performance specifications such as the European norms should be controlled at source and not in the field. For this reason future binder production should shift towards the European model where all binder components are blended together at the cement facility.

|

Table 2: high clinker substitution impacts on the plant of the future |

||

|

|

Today |

Future |

|

Component receiving |

Some |

More extensive |

|

Component drivers |

In the mill |

Separate equipment |

|

Gypsum hydration |

In the mill |

Separate equipment |

|

Mills |

Few vertical cement mills |

More, smaller, newer-technology mills |

|

Separators |

Third generation |

Ultra-high efficiency |

|

Binder actvation |

No |

Yes, binder specific |

|

Binder blenders |

No |

Yes, high speed |

|

Silos |

Few, large bulk cement |

More, smaller, components and blends |

Future cement plants may need to include the facilities to receive, store and process each of the binder components individually. Many SCMs and inert materials need to be dried before processing. In the past the heat from the hot clinker combined with the heat generated in the grinding process was sufficient to dry the modest amount of cement additives and achieve the required amount of gypsum dehydration. This may not be the case when hot clinker is substituted with cold and possibly moist additives. Separate drying of the clinker substitutes may become a necessary step before the additional components can be ground.

This problem may be exacerbated by the addition of synthetic gypsum to the binder. ‘Synthetic gypsum’ is the term applied to gypsum created in flue gas desulphurisation (wet) scrubbers used in some power and cement plants. As the number of scrubbers increases, this material is becoming increasingly more prevalent and less expensive than natural gypsum. It also has a higher moisture content and is more difficult to handle. Gypsum (natural or synthetic) should be at least partially dehydrated to improve solubility and cement performance. This dehydration may need to be independently controlled in a separate operation.

Today’s tendency is to use one or more vertical roller mills (VRMs) for cement grinding. VRMs may not be able to grind the harder binder components to a sufficient fineness. They also may not develop enough heat to adequately dry moist components such as pozzolan or slag.

The future cement plant is likely to have more individual mills dedicated to one or more of the binder components. Each mill should be designed for that specific binder and in some cases, could include VRMs. However, as binder finenesses increases new milling technologies such as stirred media mills and jet mills may need to be introduced.

Finer grinding will also require better classification of the product. Today’s third-generation classifiers may not be adequate for obtaining the required future finenesses of the binder components. Ultra-high efficiency separators, available in small size today, may need to be scaled up to cement production size for the future.

Each SCM has its specific properties that need to be optimised for maximum substitution. Reactivity of the base component and surface area are usually the most important properties. However, additional processing and or activation may be necessary for some components.

Cement storage facilities will have to be modified to contain the individual binder components. This may require more, smaller silos than today’s large single-product storage systems. The products of the cement plant should become a series of customised blends of preground components. This will require high-speed, accurate metering and blending of the individual binder components as they are loaded for transport.

It can be seen that the ‘finish grind’ shop of today may become an expansive minerals processing plant in the future. Today’s single, large VRMs for cement grinding may be left standing, like the bones of dinosaurs in museums, to remind us of a simpler past. If you don’t believe this can happen, look back to the simplicity of an old wet-process cement plant compared to the complexity of today’s five-stage precalciner kiln using alternative raw materials and fuels. These developments were all driven by escalating fuel costs.

Summary

CO2 reductions will be required in the cement industry to meet future CO2 emissions targets. Reducing CO2 emissions are likely to change today's cement manufacturing processes. The three traditional levers for CO2 reduction alone will not be sufficient, therefore carbon capture and sequestration (CCS) will be necessary. CCS processes are under development and being piloted in a few locations around the world. However, CCS technology is expected to be expensive, both in terms of installation and operation.

Each of the traditional levers will have to be optimised to avoid requiring costly CO2 sequestration. Increasing the substitution of clinker in the cement binder is one of the more promising means to reduce CO2 emissions from cement production and concrete usage. However, as SCM supplies are limited, cement companies that want to increase clinker substitution will need to secure future SCM reserves early.

Maximising the substitution of clinker will require optimising the performance of each of the individual binder components. This will likely require separate processing lines for each individual component that could include drying, grinding and activating of that material. Each material, including clinker, should be ground to its own specific optimum fineness and probably significantly finer than today’s norms. Cement plants that maximise clinker substitution will likely have individual silos for each of the binder components which will then be custom-blended prior to shipment according to the specific customer/usage needs.

Finally, cement producers will need to promote the acceptance of binders with a high clinker substitution rate in the market place. This will take time, as the durability will need to be proven, specifications adapted and building practices adjusted. However, many good initiatives are already in place today.

Article first published in International Cement Review, November 2013.