Dear Sir

What are the possible reasons for high deflection of supporting roller.

see page 15 of the attachment.

mainly due to crank in the kiln shell (may be due to mechanical and thermal) the roller shaft got deflected,

the range is 0 to 0.15 in green zone and above 0.2 it is in red zone.

Attached files

idm-toolkit-user-manual-new.pdf

idm-toolkit-user-manual-new.pdf

Thanks Dear Niladri

In our kiln deflection of P2 varies from 0.06 to 0 .19 mm without any much change in shell temperature and kiln main drive load. Is it possible to bring down it within normal range by hot alignment of kiln?

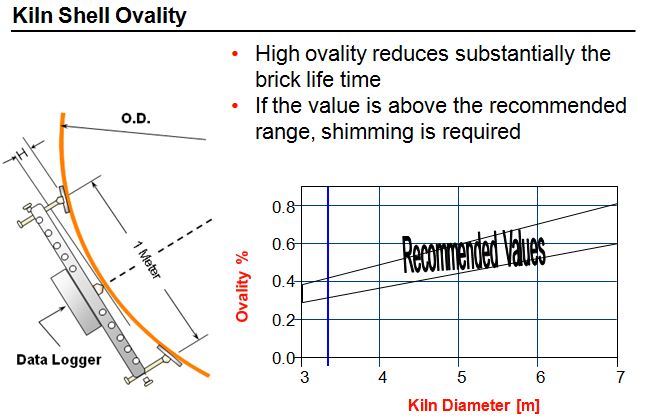

check the ovality of the kiln shell under this tyre means just within 1 mtr of the tyre.and let me know the

value .I am attaching a relation of ovality tolerence of kiln diameter and ovality. check the migration of this tyre. .

check the ovality of the kiln shell under this tyre means just within 1 mtr of the tyre.and let me know the

value .I am attaching a relation of ovality tolerence of kiln diameter and ovality. check the migration of this tyre. .

Attached files

ovality 2.JPG

ovality 2.JPG