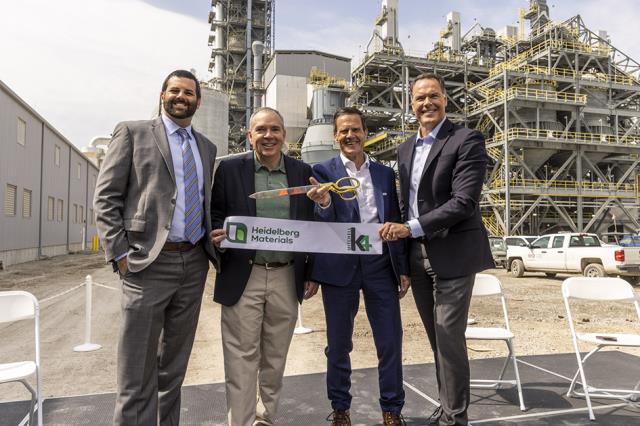

Heidelberg Materials celebrated the opening of its new cement plant in Mitchell, Indiana, USA on 13 June 2023. The state-of-the-art facility will be the second-largest cement plant in North America with a cement capacity of 2.4Mta, and one of the most technologically advanced and sustainable ever built. Heidelberg Materials' management joined customers, partners, as well as federal, state, and local officials to cut the ribbon.

“Our Mitchell project instills pride in our rich history and provides an exciting look into the future of cement production at the same time,” said Heidelberg Materials CEO, Dr Dominik von Achten: “The plant will substantially contribute to Heidelberg Materials’ offering of low-carbon cement and concrete – it is the springboard to become the first fully decarbonised cement plant in the USA. It represents our commitment to further strengthening our North American footprint and increasing the sustainability of our products.”

”The plant will reduce clinker production carbon dioxide emissions per tonne of product by almost 30 per cent mainly through operating on natural gas,” said Chris Ward, member of the Managing Board and responsible for the North America Group area. “Our investment in the Mitchell facility helps us lower our carbon footprint while serving the growing demand for more sustainable products in this key market.”

Mitchell is also where Heidelberg Materials’ largest carbon capture, utilisation and storage (CCUS) project to date will be located: The company aims to capture 95 per cent of the CO₂ emissions from the newly-renovated production facility and store them in a local onshore reservoir in the Illinois Basin by 2030. This corresponds to an emission reduction of approximately 2Mta of CO₂. Heidelberg Materials is currently conducting a feasibility study at the site, supported by the US Department of Energy.

A noticeable feature of the site is the 66m-wide, 50m-high storage dome, which can hold 154,000tof clinker. The structure was built with Heidelberg Materials’ EcoCem PLC™, a durable cement produced with a significantly smaller carbon footprint. The new facility will produce EcoCem and other sustainable products.

With the increased capacity, Heidelberg Materials is also improving the plant’s distribution process. The company will be bringing on an additional 1,000 rail cars to serve the newly renovated rail yard near the site lowering road traffic and saving CO₂. The new distribution terminal accommodates 32,000t of additional cement storage.

A new automated laboratory, a smart motor control centre to collect and communicate data, and a high-speed automated rotary-type packing machine capable of filling 3600 bags per hour will dramatically increase efficiency.

Heidelberg Materials and community leaders cut ribbon at Mitchell, Indiana, USA, cement plant (3rd from left:

Dr Dominik von Achten, CEO of Heidelberg Materials, and 4th from left: Chris Ward, member of the Managing Board

of Heidelberg Materials and responsible for the North America Group area)