Geometrica designs some of the world’s largest free-span domes, trademarked as Freedomes®, as a solution for challenging architectural and logistical feats across the Middle East. Freedome technology "has revolutionised the installation process on any terrain," according to the company, and below are case studies of cement plant projects undertaken for key producers across the Middle East.

Star Cement, UAE

The United Arab Emirates is well known for its cement production, refineries and other industrial pursuits. One particular area holds a unique distinction. Ras Al Khaimah (or RAK) is a large cement-producing region, with output that has helped develop the country and spur the infrastructure of neighbouring Dubai and Abu Dhabi. To continue this growth, Star Cement, part of the ETA group, built a new state-of-the cement plant in RAK with a clinker capacity of 7000tpd.

An immense circular dome covers a ring stockpile at Star Cement, UAE

The biggest challenge was the enormous nature of the limestone stockpile, explains Geometrica. A week’s worth of limestone amounts to 34,000t and has a diameter of 92 meters. Star Cement's civil and structural consultant, FLSmidth Designs Pvt Ltd, India, drafted a performance specification that included all dimensional and loading requirements for the stockpile cover. It was required to allow ample clearance for the stacker-reclaimer system, provide an opening for the incoming conveyor as well as four entrances for off-road vehicles, and include space for a traffic lane inside the dome around the ring rail of the reclaimer.

Crucial to the schedule was Geometrica's ability to accommodate the stacker-reclaimer and the conveyor gallery while building the structure, the company continues. Once the structure was complete, the second pour of the concrete edge beam was completed and the cladding installed. The cladding used for this structure consists of simple rectangular panels of “Star Cement Blue” laid out in a 12-slice arrangement.

Translucent fibre-reinforced plastic panels form chevron-shaped skylights that make interior artificial light unnecessary during daylight hours. Notably, the desert sand added its own hue to the blue cladding.

Ras Al Khaimah Cement, UAE

Ras Al Khaimah Cement Company, also based in the UAE, contracted Geometrica to provide coal storage and installed a longitudinal dome dedicated to sustainability. The plant is designed to meet the most stringent European standards for environmental protection.

The vault extends an impressive 140m in length and was installed over concrete walls that contain the coal stockpile. The dome design included natural ventilation and lightning protection systems to help control the potential fire and explosion hazards associated with storing coal.

Cimento Sanayi ve Ticaret, Turkey

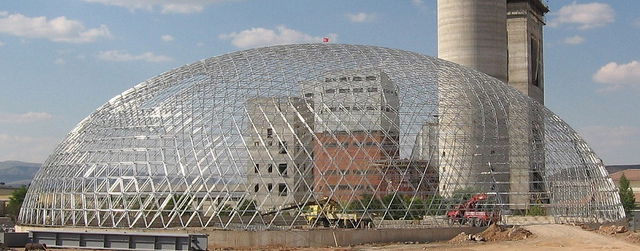

Cimento Sanayi ve Ticaret added a limestone storage dome spanning 68m to its facilities in Kayseri, Turkey, to further meet the demands of both domestic and overseas customers in several sectors. With sustainability of key importance, Geometrica designed a circular stockpile cover to prevent runoff and particulates from harming the environment.

Geometrica also designed two 68m blending domes for Cimsa's Mersin plant. The domes helped achieve sustainability and environmental objectives.

A 68m storage dome under construction in Kayseri, Turkey