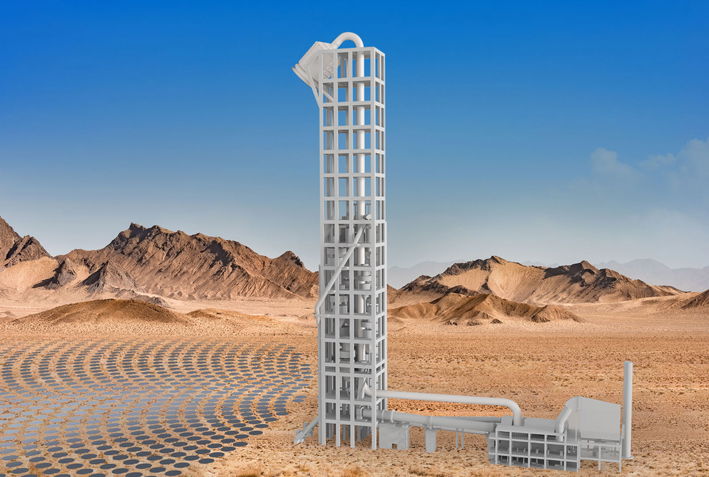

Cemex and Synhelion SA have developed a groundbreaking technology designed to fully decarbonise the cement manufacturing process based on solar energy.

The new approach is based on replacing the use of fossil fuels in cement plants with high-temperature solar heat, and capturing 100 per cent of the carbon emissions, enabling cement manufacturing to achieve net-zero level. This is made possible by the unprecedented temperature levels of solar heat provided by Synhelion's technology and its pioneering process to turn CO2 into synthetic drop-in fuels, such as kerosene, diesel and gasoline.

Following the research collaboration completed in spring 2020, Cemex and Synhelion plan to adopt a staged approach towards implementing the technology. A pilot installation is expected to be incorporated into an existing Cemex cement plant by the end of 2022 and gradually extended to a fully solar-driven plant.

"Our solar receiver demonstrably provides process heat at unparalleled temperatures beyond 1500°C, and offers a clean alternative to burning fossil fuels," said Gianluca Ambrosetti, CEO of Synhelion. "The CO2 emissions from the cement manufacturing mix with the heat transfer fluid for our solar receiver and are integrated into the process. As we are working in a closed-loop system, the CO2 emissions can be easily extracted. We then close the carbon cycle by using CO2 to produce fuels."

"We are witnessing a completely novel way to manage the emissions from cement production by using solar heat in an advanced and sophisticated manner," said Davide Zampini, Cemex Head of Global R&D and IP Management. "The partnership with Synhelion reinforces our determination to decarbonise cement production and is the outcome of our persistent R&D efforts to develop sustainable solutions as well as identify strategic partners at the forefront of innovation. Synhelion shares our commitment to closing the carbon cycle and our collaboration should enable Cemex to accelerate the pace towards achieving its net-zero CO2 ambition for 2050."

Cemex signs a contract with Synhelion for solar cement plant trials