Claudius Peters Projects GmbH has won the contract to supply the basic and detail engineering, mechanical equipment, erection and supervision, as well as the commissioning for the upgrade of the dosing and transport of grey kiln dust and chalk dust, at the cement plant of Aalborg Portland A/S, Denmark (Cementir Group). Chalk and grey kiln dust will together with calcined clay be used to substitute clinker for CO2 reduction.

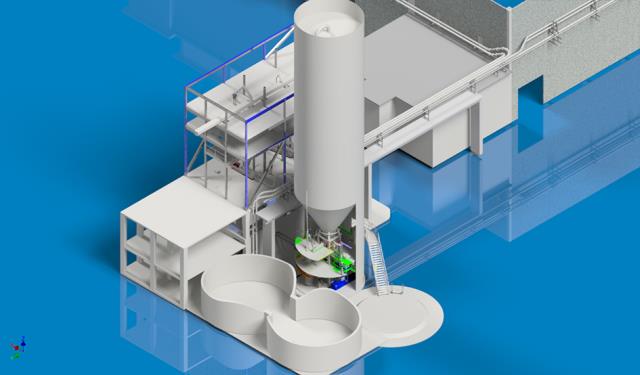

Planning in an existing building is always a special challenge. For this purpose, Claudius Peters Projects created a 3D scan on site. Furthermore, a material test was carried out at the technical centre, which led the customer to decide in favour of a C-Lever® flow meter system. Another important requirement from the customer was the implementation of an existing pressure vessel system as well as ensuring continuous operation of the cement mills during assembly.

In addition to the modernisation of the chalk steel silo aeration, discharge and distribution system, Claudius Peters Projects GmbH will also supply:

• four CPP X-200 pumps with two integrated hopper dedusting filters

• four energy-saving “Hybrid Rotary Blowers” with piping

• a set of silo aeration panels with separate aeration blower

• three CPP flow control gates PCD

• two dosing rotary valves

• four mass flow meters “C-Lever® 50 direct (PSE)

• four conveying lines with pneumatic slide gates at the ends and complete supporting structure

• one dedusting filter cyclone with rotary feeder and discharge chute.

The required electrical installation and integration into the plant control will be carried out by the customer.

Aalborg Portland Chalk silo model