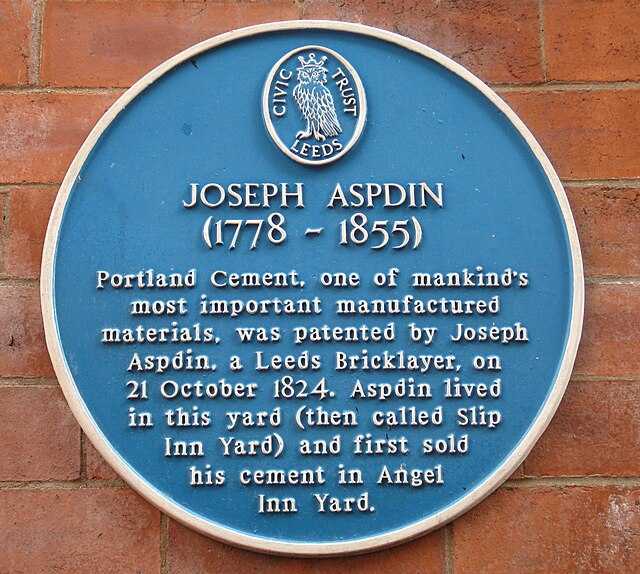

200 years ago today, on 21 October 1824, the patent for Portland cement was granted to Joseph Aspdin (1778-1855), a bricklayer and inventor from Leeds, UK.

The product was called Portland cement because of the resemblance of the hardened concrete to Portland stone, a limestone quarried on the Isle of Portland in Dorset, UK.

Portland cement, patented by Joseph Aspdin on 21 October 1824

Mr Aspdin, along with contemporaries including Louis Vicat (hydraulic limes), Isaac Johnson (significance of high temperature in cement manufacture) and Frederick Ransome (patented the rotary kiln), laid the foundations for the modern cement industry.

Since then, cement and concrete have played a crucial role in creating the global built environment, providing the structures for the housing of a growing world population and the infrastructure that is essential for human activity, including transport, water, energy systems, as well as for other basic services, including education and healthcare.

Today, over 4bnt Portland cement is produced worldwide each year, according to The Global Cement Report, 15th Edition, while concrete is one of the world’s most widely-used man-made materials, unparalleled in terms of its versatility, longevity and performance.

Challenges remain

However, the significant industrial milestone comes at a time when according to the Mineral Products Association (MPA), the UK Government’s recent draft Industrial Strategy Green Paper risks missing an opportunity to deliver support for industries such as cement which are vital to the UK’s infrastructure and development pipeline.

Net zero is a major opportunity for growth in the cement industry, with capacity for carbon capture and storage a clear natural advantage for the UK if the opportunity is fully supported.

The MPA is also calling for the introduction of a watertight UK Carbon Border Adjustment Mechanism to level the carbon and energy policy costs between importers and domestic producers.

The MPA's Executive Director, Energy and Climate Change, Cement and Lime, Dr Diana Casey, said: “As we celebrate the bicentenary of UK cement production, our industry has a clear commitment to net zero and UK manufactured cement remains essential to delivering the UK’s energy transition and development pipeline.

“It’s therefore important that Government continues to back the sector’s decarbonisation and UK construction buys cement that is responsibly sourced and made in cement kilns that are decarbonising.”